Elevator Rope Socket: Function, Types, and Importance in Elevator Safety

When it comes to elevator systems, every component plays a vital role in ensuring safety, reliability, and smooth operation. One of the most critical yet often overlooked components is the elevator rope socket. Whether it’s a traction elevator in a high-rise building or a freight elevator in an industrial space, rope sockets are essential for connecting and securing the elevator’s suspension ropes to the car or counterweight system.

In this article, we’ll explore what elevator rope sockets are, their types, functions, and why choosing the right one matters for performance and safety.

Welcome to WordPress. This is your first post. Edit or delete it, then start writing!

What Is an Elevator Rope Socket?

An elevator rope socket is a mechanical fitting that connects the suspension rope (or hoist rope) to the elevator car or counterweight. It provides a firm and secure termination point, ensuring that the rope can effectively transmit the lifting force without slipping or coming loose.

In simple terms, the rope socket acts as a bridge between the elevator ropes and the elevator structure, holding them firmly under tension.

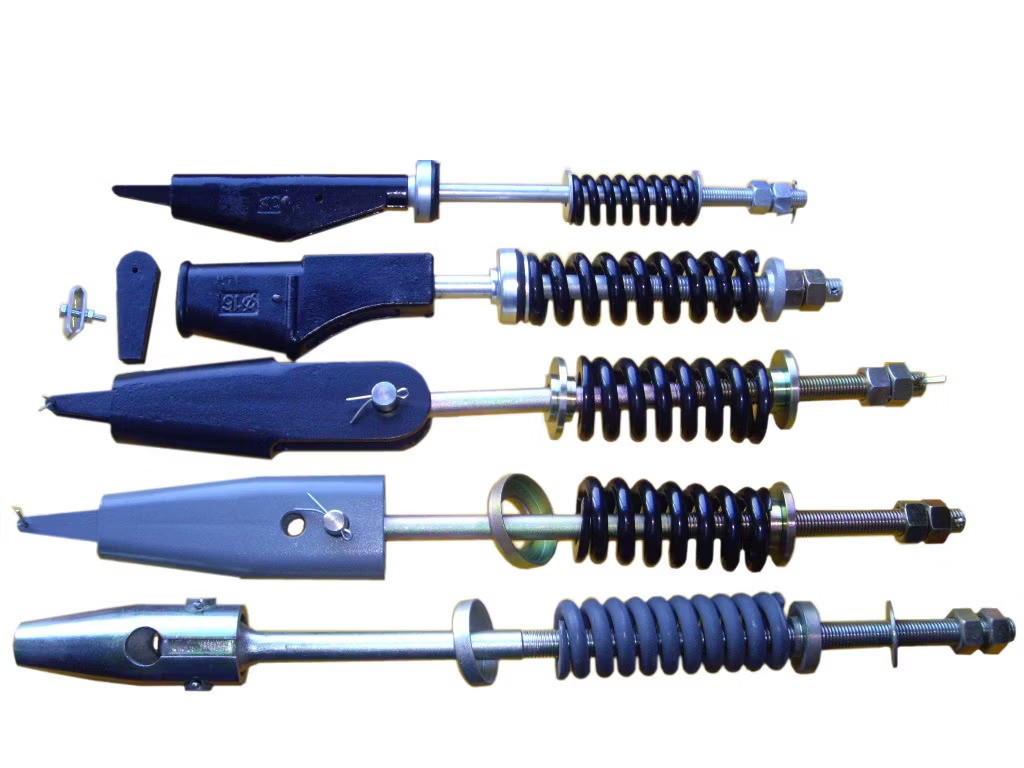

ypes of Elevator Rope Sockets

There are several types of rope sockets used in modern elevator systems. The choice depends on the elevator design, load requirements, and the type of ropes used.

1. Wedge Type Rope Socket

This is the most commonly used type. It works by wedging the rope securely inside the socket body. The design allows easy installation and removal, making it ideal for maintenance and inspection.

Benefits:

- Simple and fast installation

- Easy rope replacement

- High grip strength

2. Conical Type Rope Socket

The conical socket uses a cone-shaped fitting that grips the rope ends securely with the help of a special zinc or resin compound. It’s commonly used in heavy-duty and high-load applications.

Benefits:

- Superior strength

- Reliable long-term performance

- Best suited for high-rise or high-capacity elevators

3. Swaged Rope Socket

This type is permanently attached to the rope using mechanical or hydraulic pressure. It’s often used when a permanent, maintenance-free connection is required.

Benefits:

- Permanent and tamper-proof

- Ideal for factory-assembled systems

- Excellent fatigue resistance

Why Rope Sockets Are Important in Elevator Systems

The reliability of an elevator system depends greatly on the integrity of its connections. A properly installed and maintained rope socket ensures:

- Passenger Safety: Prevents slippage or rope detachment, ensuring the elevator remains securely suspended.

- Operational Efficiency: Reduces vibration and wear, allowing the elevator to run smoothly.

- Easy Maintenance: Wedge-type sockets allow for quick inspection and rope replacement, minimizing downtime.

- Longer Rope Life: Properly designed sockets distribute the load evenly across rope strands, preventing premature wear.

Material and Quality Considerations

Elevator rope sockets are typically made from high-grade steel or ductile iron for maximum strength and durability. Quality assurance is crucial—poor-quality sockets can cause uneven tension, slippage, or even rope failure.

When selecting a rope socket, ensure it meets international elevator standards such as EN 81, ISO 4344, or equivalent local safety codes. Always source from trusted elevator component manufacturers or suppliers with certified quality management systems.

Installation and Maintenance Tips

- Always follow the manufacturer’s torque and assembly guidelines.

- Check for any corrosion, cracks, or deformation during regular maintenance.

- Replace sockets that show signs of wear or damage immediately.

- Use only approved rope lubricants and avoid contamination during installation.

Routine inspection of the rope socket connection is a key part of elevator preventive maintenance and ensures long-term operational safety.

The elevator rope socket may seem like a small component, but it plays a crucial role in the overall safety and reliability of the elevator system. Choosing the right type, ensuring quality installation, and maintaining it properly can significantly enhance performance and extend the service life of both the ropes and the elevator.

No responses yet